Improven is groot geworden met het beheersen, verbeteren en innoveren van processen. Dat is dan ook wat we tot op de dag van vandaag, samen met onze klanten, het allerleukst vinden om te doen! Vanuit een oprechte nieuwsgierigheid naar hoe organisaties werken, verbeteren wij processen met passie en ervaring. In dit blog nemen wij je mee in hoe wij onze filosofie van continu verbeteren in de praktijk brengen. Want, en daar geloven wij oprecht in, het kan écht altijd beter!

De uitdaging bij deze netbeheerder

Anderhalf jaar geleden startten wij samen bij een van de grootste netbeheerders van Nederland. De energiesector staat voor de grootste uitdaging ooit: de energietransitie. Kort gezegd betekent dit de overgang van een fossiel-gedreven energiesysteem naar een duurzaam, decentraal georganiseerd systeem met aandacht voor energiebesparing en -opslag.

Deze transitie heeft enorme impact op de bedrijfsvoering van deze netbeheerder. De vraag naar elektrische auto’s, warmtepompen en zonnepanelen groeit explosief. Sinds 2023 bestaat meer dan 54% van de energieconsumptie in Nederland uit opgewekte elektriciteit. Dit betekent dat het elektriciteitsnet veel zwaarder wordt belast dan de afgelopen 50 jaar. Het gevolg? Netcongestie: overvolle elektriciteitsnetten die kunnen leiden tot stroomuitval. In bepaalde regio’s in Nederland is het nu al zo dat bij piekmomenten de elektriciteit uitvalt.

De netbeheerder heeft een heldere belofte: In 2030 willen we klanten oplossingen bieden die passen bij een betaalbaar en betrouwbaar energiesysteem en zo bijdragen aan een klimaatneutraal Nederland in 2050.

Om deze ambitie waar te maken, is optimale communicatie binnen en tussen ketens cruciaal. Wij kregen de opdracht om de slimme meterketen te verbeteren – een proces dat bij de start van ons project niet optimaal functioneerde.

De slimme meterketen: wat was het probleem?

Het incidentmanagementteam van de slimme meterketen is verantwoordelijk voor het analyseren van storingen en het identificeren van oorzaken. Onze analyse bracht twee grote knelpunten aan het licht:

- Veel onterechte storingsmeldingen zorgden voor ruis en vertraging.

- Inefficiënte verwerking van storingen leidde tot lange doorlooptijden.

Een van de kernprincipes van Lean Six Sigma is het elimineren van verspilling. Onterechte storingsmeldingen en lange doorlooptijden zorgen voor onnodige kosten en vertragingen in processen. Met Lean Six Sigma kunnen organisaties deze verspilling niet alleen identificeren, maar ook structureel aanpakken.

Deze methodiek helpt niet alleen bij het wegnemen van knelpunten, maar ook bij het optimaliseren van processen. Door storingen efficiënter te verwerken en slimmer te organiseren, kunnen we doorlooptijden verkorten en de prestaties verbeteren.

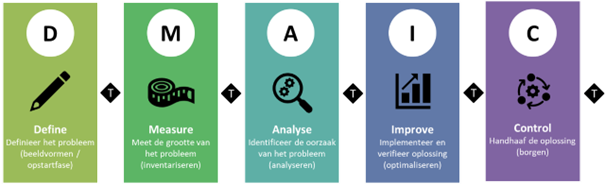

De reden dat deze methodiek zich perfect leende voor deze situatie. Met behulp van deze methodiek en het DMAIC-model (Define, Measure, Analyze, Improve, Control) hebben we deze uitdagingen aangepakt. In deze blog nemen wij je mee door de vijf stappen die we hebben doorlopen.

Afbeelding 1.1. Het DMAIC-Model

1. Define (Definiëren)

In deze fase hebben we het probleem scherp gesteld, projectdoelen geformuleerd en klantwensen opgehaald. We brachten het proces in kaart, stelden een SIPOC op en bepaalden de projectscope.

Uit deze analyse kwamen twee duidelijke focuspunten:

- Het verminderen van onterechte storingsmeldingen.

- Het verkorten van de doorlooptijd van incidenten.

Deze focuspunten werden omgezet in key metrics die de basis vormden voor de rest van het project.

2. Measure (Meten)

Vervolgens hebben we data verzameld om de huidige prestaties van het proces te begrijpen. We bepaalden de doorlooptijd en het aantal terechte storingen als nulmeting.

Deze metingen gaven ons inzicht in waar de grootste vertragingen en inefficiënties zaten – cruciale informatie voor de volgende fase.

3. Analyze (Analyseren)

In deze fase hebben we samen met het team de oorzaken van de problemen grondig onderzocht. We gebruikten verschillende analysemethoden, waaronder:

- Visgraatdiagram: om samen met het team mogelijke oorzaken te categoriseren.

- De ‘5x waarom’-methode: om tot de kern van het probleem te komen.

- Data-analyse: om kwantitatieve inzichten te koppelen aan kwalitatieve bevindingen.

De analyse onthulde drie hoofdoorzaken “rootcauses”:

- Vervuilde instroom door onterechte meldingen.

- Handmatige, foutgevoelige werkzaamheden.

- Een gebrek aan vertrouwen binnen de keten.

4. Improve (Verbeteren)

Met deze inzichten ontwikkelden we gerichte oplossingen. We prioriteerden deze initiatieven met behulp van een Impact-Effort Matrix – zo richtten we ons op acties met de grootste impact en haalbaarheid.

De belangrijkste verbeteringen:

- Het optimaliseren van de business rules van het vorig jaar geïmplementeerde eventmanagementsysteem, om foutgevoelige handmatige taken verder te automatiseren en te verbeteren.

- Investeren in teambuilding om het vertrouwen en de samenwerking binnen het team te versterken.

- Het introduceren van structurele overleggen en dashboards voor beter inzicht en grip op het proces.

- De invoering van een verbeterbord, waarop het team verbeteracties en voortgang visueel bijhoudt. Dit stimuleert continue optimalisatie en zorgt voor meer eigenaarschap binnen het team.

Deze maatregelen brachten structuur en eigenaarschap terug in het team en de keten.

5. Control (Beheersen)

Duurzame verbetering vereist borging. In deze fase hebben we controlemechanismen ingevoerd om te zorgen dat de verbeteringen blijvend zijn.

Na negen maanden hebben we opnieuw metingen uitgevoerd. De resultaten?

- 58% minder storingsincidenten door het verminderen van onterechte meldingen.

- 80% kortere doorlooptijd van incidenten.

Het resultaat is een efficiënter en gemotiveerder team dat storingen sneller en effectiever afhandelt – en dat merken de klanten!

Blijven verbeteren: de sleutel tot een wendbare organisatie

Succesvolle verbetering stopt niet na één project. Dit traject bij deze netbeheerder laat zien hoe krachtig de combinatie van data-analyse, procesdenken en samenwerking kan zijn. Met Lean Six Sigma hebben we niet alleen directe resultaten behaald, zoals minder storingsincidenten en kortere doorlooptijden, maar ook een sterke basis gelegd voor blijvende vooruitgang. Door continu te blijven optimaliseren, kunnen organisaties flexibel inspelen op veranderingen en toekomstbestendig blijven. Blijven verbeteren is geen eenmalige actie, maar een mindset die zorgt voor langdurig succes.

Wil je weten hoe wij jouw organisatie kunnen helpen met procesoptimalisatie en duurzame verbeteringen? Neem gerust contact op met een van de auteurs, Tim of Ymke. Wij vertellen je graag meer!

Tim Hengeveld